If you’re in the business of moving products, chances are you’ve heard of cross-docking. But what is cross docking exactly? And how can it benefit your business? Here’s a quick rundown of everything you need to know about cross-docking.

What is Cross Docking?

Cross-docking is a supply chain management process that involves transferring goods from one source to another in a warehouse environment. It enables goods to move quickly and effectively between supply points without being stored in the warehouse. To accomplish this, supply points are distributed around a cross-dock warehouse complex where incoming goods are loaded directly onto the outbound carriers according to their shipping specifications. Cross-docking facilities can be used by companies large or small, allowing them to have streamlined supply chain control, the efficiency of movement, reduced costs, and decreased delivery time. Ultimately, it helps operators reduce inventory levels for better supply chain management.

The benefits of cross-docking

Cross-docking is becoming an increasingly popular method of inventory management, and it’s easy to see why. With cross-docking, labour costs are kept low since merchandise doesn’t need to be stored or handled as much. It also provides businesses with huge time savings by eliminating the need for waiting periods during order fulfillment. Everyone involved in the process can also benefit from improved tracking methods due to less of a chance of something going wrong along the way. All in all, businesses should consider leveraging cross-docking if efficient inventory management is important to them.

What are the different Types of Cross Docking?

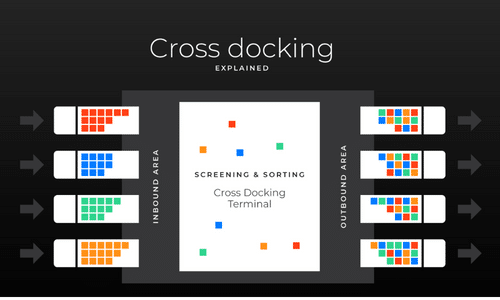

Cross docking can often be thought of as a complex and overwhelming process, but it is quite simple. There are generally two types of cross-docking: inbound and outbound. Both types involve the quick and efficient movement of goods from suppliers to customers without any extensive storage time in between. Inbound cross-docking involves the unloading, sorting or packaging of supplied goods to prepare them for distribution or immediate shipment. On the contrary, outbound cross-docking requires that goods be loaded, combined with other commodities for consolidation, and distributed quickly to retail stores or direct to customers.

Types of products that can be cross-docked

Cross-docking is an effective strategy for a wide range of products, such as fresh produce, beverages, health and beauty items, and IT equipment. Utilizing this method within your warehouse facility can help streamline the process to increase efficiency. Cross-docked items save business owners valuable time because each item does not require the same amount of attention from warehouse staff as the process is streamlined. With Cross-docking you can optimize inventory levels and redistribute any leftover retail products back out to stores. This helps warehouse owners maximize their resources, ensuring that no product goes unused! Using cross-docking techniques at a warehouse facility can result in significantly greater efficiency and cost savings compared to traditional warehouse practices.

Outline the process of how cross-docking works

Cross-docking is a process that involves taking items from suppliers, cross-referencing them with distribution centers, and quickly distributing them to their final destinations in a timely manner. The cross-docking process is typically carried out in a logistics hub or warehouse where incoming products are unloaded, sorted, and then loaded onto delivery vehicles or outbound shipping containers as quickly as possible. This helps reduce costs by minimizing the need for extensive storage areas in distribution centers and also speeds up delivery times significantly

Examples of companies that use cross-docking

Cross-docking has become a popular logistics strategy among many companies today. Transportation cross-docking uses data and transportation networks to move goods from shippers to retailers while reducing shipping times and transportation costs. Retail cross docking is similar in that it focuses on the transfer of goods within retail stores, providing faster turnaround times and less need for storage space. In manufacturing, cross-docking allows for raw materials to be consolidated for delivery to necessary locations with assembly operations, reducing transportation costs, delays, and storage needs; resulting in shorter cycle times and lower overall production costs. Companies that have successfully integrated cross-docking strategies into their business models include Amazon, Walmart, Dell Technologies, Unilever, and General Mills.

About Evolution Fulfillment

Evolution Fulfillment – located near Vancouver, BC – provides professional transloading and cross docking services for companies with goods coming into North America and/or for distribution throughout Canada.

If you’re interested in learning more about our 3PL services in Canada and in the US, visit our website at www.evolvewithus.ca.